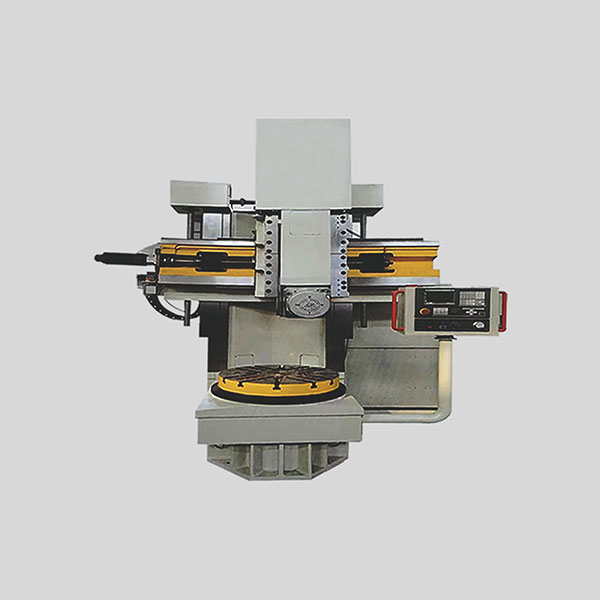

CGK51 series high speed CNC single column vertical lathe

1. This series of machine tools is CNC single column vertical lathe, using advanced design and manufacturing technology at home and abroad. Suitable for carbide and ceramic cutting tools, black metal, non-ferrous metal and some non-metallic parts of the inner and outer cylindrical surface, inner and outer conical surface, end face, grooving thread and rotary surface, etc.

2. High-speed cutting: the maximum cutting speed can reach 2000m/min. The tool holder moves fast (up to 12m/min horizontally and vertically.

3. The main drive is driven by two-speed AC servo motor, high-speed rotation accessories are static and dynamic balance, transmission gear adopts grinding process, to achieve high transmission efficiency, low noise, reliable and stable operation at high speed.

4. The feed system is driven by AC servo motor, which is directly connected with ball screw to achieve gapless transmission and high running accuracy.

5. The column is a thermal symmetric structure, the column is installed on the base of the workbench, through the finite element method calculation, take effective vibration isolation measures, with high stiffness, high vibration resistance.

6. The table for the thermal symmetry structure, the main shaft using high-precision adjustable radial clearance of the double row short cylindrical roller bearing centering, the shaft has always used high-precision large-scale thrust ball bearings rolling guide, and equipped with oil temperature cooling device, therefore, the table has high rotation accuracy, large bearing capacity, small thermal deformation characteristics.

7. The feed movement of the tool holder and ram, the use of rolling ball screw and linear bidirectional roller rolling guide to make the tool holder run smoothly, high transmission efficiency, good accuracy retention.

8. Can be selected by the user numerical control system.

9. The machine can be equipped with chip removal device and semi-closed, fully closed protective cover.

10. According to user needs, can provide tool library, machine tool device, milling and boring function, table indexing and feed function, grinding function, left vertical tool holder and full closed-loop control.

Product drawing, sample parameters change with the development of technology, without further notice.